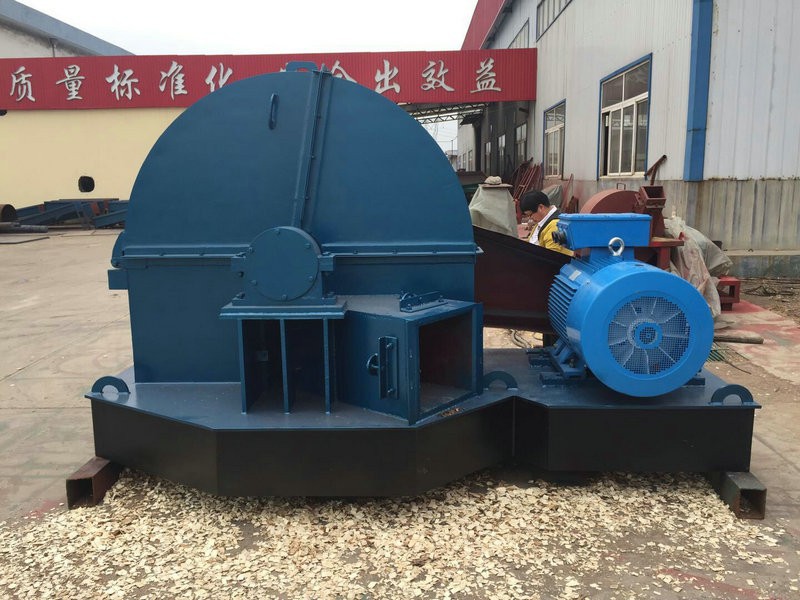

Wood chip machine, also known as die-cutting machine or wood chip cutting machine, is mainly used to process wood into wood chips of a certain size and shape for pressing into various products, such as plywood, pulp board, etc. Wood chip machines are widely used in the wood processing industry.

Wood chip machine structure is roughly divided into the following parts:

1. Machine base: The machine base is the foundation of the wood chip machine and is used to fix other components.

2. Feeding system: The feeding system is mainly composed of feeding rollers and feeding plates, and the wood chip machine is used to feed wood to the cutter.

3. Cutting system: The cutting system of the wood chip machine is mainly composed of a knife wheel and a knife frame, which is used to cut wood into wood chips.

4. Discharging system: The discharging system is mainly composed of a discharging plate and a discharging roller, which is used to transfer the cut wood chips to the next working link.

5. Control system: The control system mainly includes an electrical control box, a motor and a transmission device, etc., which are used to control the normal operation of the wood chip machine.

The working principle of the wood chipper is to send the wood to the cutting system through the feeding system, and the cutting wheel drives the knife frame to operate and cut the wood into wood chips of a certain size and shape. After cutting, the wood chips are sent to the next processing link through the discharging system to realize automated production.

This article introduces the function, structure and working principle of the wood chipper in detail. By understanding the structural principle of the wood chipper, it helps us to have a deep understanding of the wood chipper, further improve the processing efficiency, and better serve the wood processing industry.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com